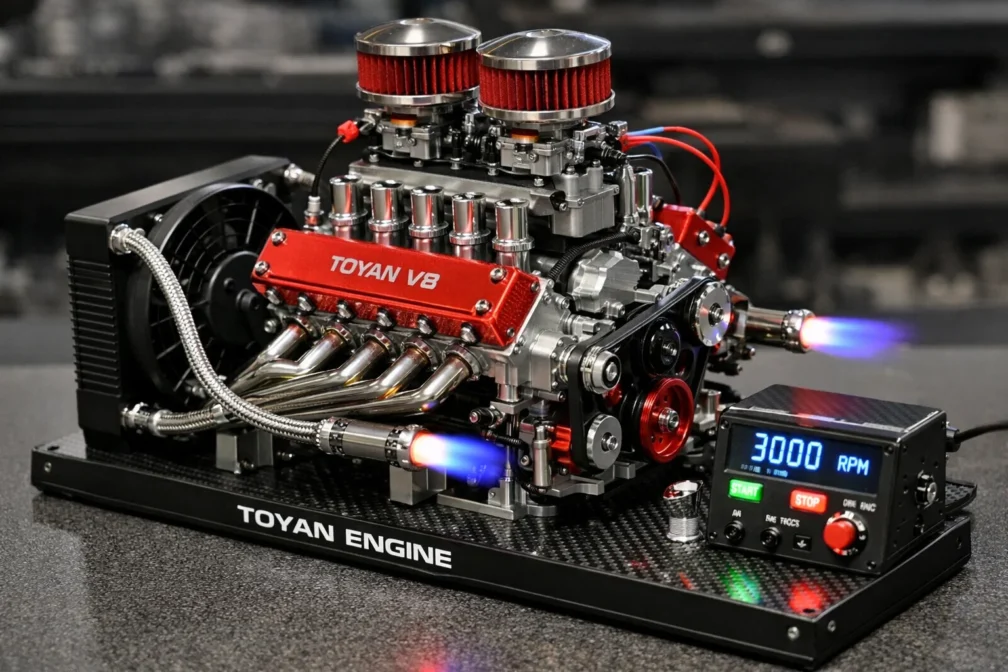

enginediy Toyan V8 engine model kit that works;There is a unique thrill that comes from holding a fully functional, roaring engine in the palm of your hand—a sensation once reserved for professional mechanics and master machinists. Today, that thrill is accessible, packaged in a box of meticulously machined metal parts. The enginediy toyan v8 engine model kit that works represents the pinnacle of this democratized engineering marvel. It is not a static display model; it is a true four-stroke, gasoline-powered V8 engine in a 1:4 scale, complete with a functional carburetor, electronic ignition, and a deafening exhaust note.

This article is your definitive guide to understanding, building, and appreciating this extraordinary piece of mechanical art. We’ll explore its origins, the profound skills it teaches, the meticulous assembly journey, and the vibrant community it has sparked. For anyone fascinated by the symphony of pistons and crankshafts, this kit is more than a project; it’s a rite of passage into the heart of mechanical mastery.

The Allure of Functional Model Engineering

Functional model engineering is a hobby that bridges the gap between abstract theory and tangible, kinetic reality. It moves beyond the plastic snap-together kits of childhood into a realm of cold, hard metal, precise tolerances, and real thermodynamic principles. Enthusiasts are drawn not to the final product alone, but to the profound understanding gained through the process of creation. Building a working engine from hundreds of individual components cultivates patience, precision, and a deep, intuitive grasp of how mechanical systems interact and depend on one another.

The enginediy Toyan V8 sits at the apex of this pursuit. It answers a fundamental question: “What makes it work?” by allowing you to construct the answer yourself, piece by piece. The appeal is multifaceted, combining the satisfaction of a complex puzzle, the pride of craftsmanship, and the visceral excitement of a first successful startup. This isn’t merely about ownership; it’s about authorship. You become the architect, assembler, and tuner of a miniature powerplant, gaining an unmatched appreciation for one of humanity’s most transformative inventions.

Unboxing the Toyan V8: A First Look at Precision

Opening the enginediy Toyan V8 kit for the first time is an experience in itself. You are greeted not by plastic, but by an array of small, gleaming metal parts—aluminum alloy castings, stainless steel shafts, brass fittings, and precisely cut gears, all individually bagged and organized. The weight and sheen of the components immediately communicate quality and seriousness. Alongside the metal, you’ll find essential sub-assemblies like the pre-wound ignition coil, spark plugs, fuel line, and the all-important CDI ignition unit. A comprehensive tool kit is typically included, featuring hex wrenches, screwdrivers, and assembly fixtures designed specifically for the task.

The initial inventory process is critical. The instruction manual, often a detailed pictorial guide with some translated text, will have a parts list. Methodically checking off each item is your first act of diligence. This step familiarizes you with the components, their names, and their eventual roles in the greater assembly. Look for hallmark pieces: the finely machined cylinder block, the crankshaft with its counterweights, the set of eight miniature pistons and connecting rods, and the intricate cylinder heads. Holding these parts, you begin to mentally map the journey ahead, from a box of disparate pieces to a unified, living machine.

The Anatomy of a Miniature Powerhouse

To appreciate the enginediy toyan v8 engine model kit that works, one must understand its scaled-down yet fully realized anatomy. It mirrors its full-sized counterpart in almost every detail. The engine block forms the foundation, housing the rotating assembly. Inside, a forged steel crankshaft converts the linear motion of the pistons into rotation, while the connecting rods and aluminum pistons replicate the combustion cycle. Overhead, the cylinder heads contain the valve train, with tiny rocker arms actuated by a pushrod system from a central camshaft nestled in the engine block’s valley.

The supporting systems are what transform this from a static model to a runner. A dual-choke carburetor mixes air and fuel, drawn from a separate external tank. A dedicated electric starter motor spins the flywheel for startup. The electronic ignition system, comprising a magnetic pickup, CDI unit, coil, and spark plugs, provides the precisely timed spark for combustion. Finally, an exhaust manifold channels the spent gases—and the remarkable sound—outward. Each system is a miniaturized marvel of engineering, demanding careful alignment and adjustment during assembly to function in perfect harmony.

Essential Tools and Workspace Setup

While the kit provides the fundamental tools, creating an optimal workspace will dramatically improve your building experience. Beyond the included wrenches, experienced builders recommend a few key additions. A high-quality set of precision needle files is indispensable for gently deburring parts and ensuring smooth fitment. Fine-grit sandpaper or emery cloth can help achieve perfect seating surfaces. A digital caliper is invaluable for verifying critical dimensions, and a small, sensitive torque driver or screwdriver set helps avoid stripping delicate threads. Good lighting is non-negotiable; an LED magnifying lamp saves eye strain and reveals minute details.

Your physical workspace should be clean, organized, and dedicated. A sturdy, flat table is a must. Use small containers, like pill organizers or parts trays, to separate and categorize screws, bolts, and small components by size and step. Keep the manual and any supplementary guides within easy reach. This isn’t a project to be done in a cluttered garage corner; treating it with the respect of a professional machinist’s bench sets the tone for the precision required. The process of building the enginediy Toyan V8 is as much about mental discipline and organization as it is about mechanical skill.

A Step-by-Step Journey Through Assembly

The assembly of the enginediy Toyan V8 is a structured symphony, best approached methodically. The process typically begins with the heart of the engine: the rotating assembly. This involves installing the crankshaft into the block, carefully attaching the eight connecting rods to the pistons using wrist pins and circlips, and then lowering this assembly into place. Precision is paramount here; parts must move freely without excessive play. Following this, the camshaft is installed and timed to the crankshaft via gears, ensuring the valves will open and close in exact synchrony with the piston movements—a step where absolute accuracy is critical for the engine to run.

Subsequent phases build outward from this core. The cylinder heads are mounted, with careful attention to the head gasket and the torquing sequence of the many small bolts. The valve train—pushrods, rocker arms, and adjusting screws—is then installed and set to a specified clearance, or “lash.” Finally, the ancillary systems are attached: the carburetor and fuel line, the ignition pickup and spark plugs, the starter motor, and the exhaust headers. Each subsystem is a mini-project unto itself, requiring careful reading, test-fitting, and adjustment before final installation. The manual guides you, but success hinges on patience and a willingness to double-check every connection.

Overcoming Common Assembly Challenges

Even with meticulous preparation, builders often encounter specific challenges that test their resolve. One frequent hurdle is achieving the correct valve lash. The clearance between the rocker arm and valve stem must be set with a feeler gauge when the piston is at Top Dead Center (TDC) on the compression stroke. This is a fiddly, repetitive process for sixteen valves, but it is essential for proper engine breathing and preventing damage. Another common struggle is aligning the timing gears for the camshaft and crankshaft. A mistake of a single tooth will prevent the engine from starting or running properly, requiring partial disassembly to correct.

Fuel and ignition issues are the primary culprits post-assembly. A tiny speck of debris in the carburetor’s jet can clog it, preventing fuel flow. Ensuring the fuel line is perfectly sealed and primed is also key. On the ignition side, verifying the gap on the magnetic pickup and ensuring the spark plugs are properly gapped and firing are critical diagnostics. As one seasoned builder on a model engineering forum noted, “The difference between a silent model and a roaring enginediy toyan v8 engine model kit that works often comes down to the three fundamentals: compression, spark, and fuel. Be methodical, and you’ll find the missing link.” This systematic troubleshooting is where theoretical knowledge becomes practical, rewarding expertise.

The Moment of Truth: First Startup and Break-In

After weeks or months of careful assembly, the moment of first startup is charged with anticipation. The procedure is deliberate. You’ll mount the engine on its test stand, connect a fresh battery to the starter and ignition system, fill the external fuel tank with the recommended mix (often gasoline with a small percentage of high-quality two-stroke oil for lubrication), and prime the carburetor. With everything checked, you engage the starter. The first few attempts might yield only coughing or sputtering—this is normal. Small adjustments to the carburetor’s mixture and idle speed screws are almost always required.

A successful start is unforgettable. The engine will fire, settle into a ragged idle, and then, as it warms, smooth out into a distinctive, high-pitched V8 blare. The break-in period that follows is crucial for the long-term health of your miniature engine. It involves running the engine at varying, moderate speeds for several tankfuls of fuel, allowing the piston rings to seat properly against the cylinder walls and all moving parts to wear in smoothly. This is not a time for high revs or extended full-throttle runs. It’s a careful, attentive process that solidifies the mechanical bonds you’ve created and prepares the engine for a long life of reliable operation.

Performance Tuning and Customization

Once broken in, the enginediy Toyan V8 becomes a platform for experimentation and tuning, much like a full-scale engine. Enthusiasts delve into fine-tuning the carburetion for optimal performance at different RPM ranges, adjusting the ignition timing for more power, or even fabricating custom exhaust systems to change the exhaust note and flow. Some venture into advanced modifications, like polishing ports in the cylinder heads for better airflow or experimenting with different fuel blends. The community is rich with shared data on performance tweaks, allowing builders to learn from each other’s successes.

The potential for customization extends beyond pure performance. Builders create stunning display stands from acrylic or hardwood, integrate remote throttle controls, or even install miniature superchargers available from aftermarket suppliers. The engine can be the centerpiece of a detailed scale model car or boat, though its primary use is as a stationary display. This phase of ownership transforms the project from a prescribed build into a personalized expression of mechanical creativity. The enginediy toyan v8 engine model kit that works is, therefore, not an endpoint, but a starting point for a deeper, ongoing engagement with model engineering.

Educational Value and Skill Development

The educational return on investment for this kit is immense. It serves as a hands-on masterclass in mechanical engineering principles. Builders gain a concrete understanding of the four-stroke cycle (intake, compression, power, exhaust), valvetrain kinematics, ignition timing, and carburetor theory. These are not abstract concepts but tangible realities observed and adjusted with one’s own hands. The project inherently teaches precision measurement, the importance of cleaning and preparation, and the logical, sequential nature of complex mechanical assembly.

Furthermore, it cultivates soft skills that are invaluable in any technical field: patience, meticulous problem-solving, and resilience in the face of frustrating setbacks. For young adults considering engineering careers, it’s a potent inspiration. For experienced hobbyists, it’s a satisfying test of their skills. The kit democratizes knowledge that was once confined to technical schools or apprenticeship programs. By completing it, you don’t just own an engine; you internalize the fundamental logic of how millions of engines around the world operate.

Comparative Analysis: Toyan V8 in the Model Engine Landscape

To understand the position of the Toyan V8, it’s helpful to compare it to other options in the functional model engine market. The landscape ranges from simple single-cylinder hit-and-miss engines to complex multi-cylinder replicas.

| Feature | Enginediy Toyan V8 FS-L400 | Typical Single-Cylinder Kit | Advanced Stirling Engine | Plastic Static Model |

|---|---|---|---|---|

| Engine Type | 4-Stroke, Gasoline V8 | 4-Stroke, Gasoline Single | External Combustion (Hot Air) | Non-functional replica |

| Complexity | Very High (300+ parts) | Moderate | Low to Moderate | Very Low |

| Build Time | 40-80+ hours | 15-30 hours | 5-15 hours | 2-10 hours |

| Skill Required | Advanced (Precision, Patience) | Intermediate | Beginner to Intermediate | Beginner |

| Educational Focus | Full IC Engine Systems, Timing, Tuning | Basic IC Engine Principles | Thermodynamics, Kinematics | Assembly, Appearance |

| Rewarding Output | A fully running, roaring V8 | A ticking single-cylinder | A smooth, silent cycle | A visually accurate display |

| Price Point | High (Premium Investment) | Medium | Low to Medium | Low |

This table illustrates that the enginediy toyan v8 engine model kit that works occupies the high-complexity, high-reward tier. It is not a beginner’s kit but is aimed at the enthusiast seeking the ultimate challenge and the most authentic internal combustion experience in miniature form.

The Vibrant Community and Knowledge Sharing

No builder of the Toyan V8 is truly alone. A global, passionate community exists online, centered around forums, social media groups, and video platforms like YouTube. These spaces are treasure troves of collective wisdom. Builders share detailed photo journals of their progress, post videos troubleshooting mysterious no-start conditions, and offer tips on tool modifications or sourcing replacement parts. This collaborative spirit is a defining aspect of the hobby, turning a solitary activity into a connected, supportive endeavor.

These communities also drive innovation. Members design and share 3D-printable files for enhanced tools, custom gauges, or elaborate display cases. They document performance modifications and their results, creating a living database of knowledge. For a newcomer, engaging with this community before and during the build is one of the smartest moves possible. It provides a safety net of experience, inspires with completed projects, and often provides clearer explanations for tricky steps than the translated manual. The finished engine becomes a ticket into this worldwide fellowship of makers.

Maintenance and Long-Term Care

Like any precision machine, a Toyan V8 requires proper care to ensure longevity and reliable performance. After running sessions, it’s good practice to turn off the fuel valve and let the engine consume the fuel in the carburetor bowl to prevent varnish buildup. Storing the engine in a low-humidity environment, ideally with a light coat of corrosion-inhibiting oil on external metal surfaces, will protect its fine finish. Periodically, checking fasteners for tightness—especially after the initial break-in runs—is recommended, as vibrations can loosen small screws.

If the engine will be stored for an extended period, a more thorough preservation process is wise. This involves running a fuel stabilizer through the system or completely draining all fuel, and removing the spark plugs to add a few drops of oil into the cylinders, then turning the engine over by hand to coat the cylinder walls. These simple steps mirror the care given to full-sized automotive or motorcycle engines and will keep your miniature masterpiece in ready-to-run condition for years, or even decades, to come. This ongoing stewardship is the final phase of responsible ownership.

Conclusion

The enginediy Toyan V8 engine model kit that works is far more than a sophisticated toy. It is a journey into the very soul of mechanical engineering, a demanding teacher, and a source of immense, hard-won satisfaction. From the first glimpse of the raw metal parts to the triumphant roar of a successful first start, it engages the mind and the senses completely. It demands your best—your patience, your attention to detail, and your problem-solving spirit—and rewards you with an unparalleled understanding of one of humanity’s defining technologies. Whether you are a seasoned model engineer or a dedicated novice ready for the ultimate challenge, this kit represents a landmark achievement. It is a testament to the beauty of functional mechanics and a powerful reminder that, sometimes, the greatest wonders are not just observed, but built with your own two hands.

Frequently Asked Questions

Is the enginediy Toyan V8 suitable for a complete beginner?

While deeply inspiring, the enginediy toyan v8 engine model kit that works is generally not recommended as a first-ever model engine project. Its high part count, precise tolerances, and complex systems like valve timing present significant challenges. Gaining experience with a simpler single-cylinder kit first is highly advisable to build foundational skills and confidence before tackling this advanced V8.

What kind of fuel does the Toyan V8 engine use?

The engine runs on a mixture of high-octane gasoline (e.g., 92 or higher) and a small percentage of high-quality synthetic two-stroke oil, typically at a 20:1 or 30:1 ratio. The oil is crucial for lubricating the engine’s internal components, as it does not have a separate oil system like a full-sized car. Always follow the specific fuel mix recommendations in the kit’s manual for optimal performance and longevity.

How loud is the engine when it runs?

The engine is remarkably loud for its size, producing a distinctive, high-pitched V8 exhaust note. It is not something you would run in a living room or apartment without significant consideration for others. Running it in a garage or workshop, and potentially using a small muffler attachment, is the norm. The sound is a major part of the authentic experience but does require a suitable environment.

Can you actually power anything with this engine?

While it produces a modest amount of power (typically a few hundred watts), its primary design purpose is as a stationary display model. Some advanced hobbyists have integrated it into scale model cars or boats, but this requires extensive custom fabrication for drivetrain and cooling systems. For most owners, the “work” it does is the mechanical demonstration and the educational value, not performing external work.

Where can I find help if I get stuck during the build?

The global community is your best resource. Dedicated model engineering forums, specific Facebook groups for Toyan engines, and numerous detailed build series on YouTube are invaluable. Searching for your specific issue often yields threads or videos where others have solved the exact same problem. Engaging with these communities before you start can provide crucial insights and prepare you for common hurdles.